Natural Red Iron Oxide

Natural red iron oxide Fe2O3 is a widely used chemical compound in various industries. It is a red-brown solid compound and is odorless. The main applications of this material are in the tile and paint production industries. In the rest of this article, we provide information about this product and its quality purchase for those who intend to buy natural red iron oxide.

How Natural Red Iron Oxide is produced?

Natural red iron oxide deposits are one of the valuable resources in many countries, but only a few countries are rich in this material. In these countries, iron oxide is naturally found in their lands. Natural red iron oxide powder in Iran is also found in Hormuz Island.

Hormuz Red Iron Oxide is one of the best natural red iron oxides in the world.

Extracting iron oxide from soil or Production of Red Iron Oxide involves geological and chemical processes. Iron oxide, commonly found as hematite, red ochre pigment, or Natural red Iron Oxide Pigments, is a valuable mineral used in various industries, including steel production and pigment manufacturing. Here are the steps involved in the natural extraction of iron oxide from soil:

- The natural extraction of iron oxide from soil involves a lengthy process that spans geological and metallurgical phases. It begins with the geological formation of iron oxide deposits, which develop over millions of years due to weathering and oxidation of iron-bearing minerals in rocks and soil.

Weathering is the initial step, driven by the interaction of water, oxygen, and carbon dioxide, leading to iron oxidation and ferric iron formation. Subsequently, leaching occurs as iron oxides dissolve due to the influence of acidic or alkaline waters, transporting iron ions away from their original locations.

- As weathering continues, iron ions in a solution can precipitate over time. This can happen due to various factors such as pH, temperature, and the presence of other ions. These iron oxides then settle at the bottom of water bodies or accumulate in soil layers through sedimentation, leading to a concentration of iron oxide.

As geological uplift and erosion occur over time, these iron oxide-rich layers get exposed to the Earth's surface, making them accessible for extraction. Geologists and mining companies then engage in prospecting activities to locate areas with high iron oxide content. The following steps involve mining, beneficiation, smelting, and refining, all of which require careful and precise processing, to obtain valuable iron-based products.

Wholesale Red Iron Oxide

The wholesale price of red iron oxide from the Red iron oxide factory directly has many advantages that will make more profit for people who need this material more in their industry.

The sale of bulk Red Iron Oxide will eliminate buying agents, making buying very affordable for you. Also, Buying Bulk Red Iron Oxide Powder reduces the need for frequent shopping, saving time and effort. It's especially beneficial for businesses as it streamlines procurement and cuts administrative costs.

Click here to read more about what is natural red iron oxide.

Natural red iron oxide manufacture

To buy natural red iron oxide online or from the factory, we need to get it from the red iron oxide plant that offers the best production of red iron oxide. Therefore, in this section, we will check the specifications of the best manufacturer.

High-Quality Raw Materials

The best Red Oxide company list in Iran sources raw materials from reliable, consistent iron oxide deposits. They prioritize the selection of natural iron ores with high iron content and minimal impurities, ensuring the production of vibrant and consistent red pigments.

Precise Extraction and Processing

Optimal Wholesale Red Iron Oxide manufacturing involves careful extraction and processing techniques. The manufacturer should employ advanced ore beneficiation, grinding, and chemical purification methods to achieve the desired color and consistency.

Stringent Quality Control

Quality control measures are paramount. The Red Iron Oxide Processing Plant should have a comprehensive quality control system, including thorough testing at various production stages to ensure color accuracy, particle size distribution, and product stability. So you can buy the Best natural red iron oxide.

Buy natural red iron oxide at the best price

Buying natural red iron oxide at the best price requires careful consideration of several vital points to ensure you get a high-quality product while staying within your budget. Here are the key factors to keep in mind:

Quality and Purity

Start by evaluating the quality and purity of the red ochre pigment powder. Seek out products that meet industry standards and have high purity to ensure optimal performance in your application.

Particle Size

Consider the particle size of the Bulk Red Iron Oxide. The desired particle size may vary depending on your specific application. Smaller particles may be needed for certain uses, while larger particles might suit others.

Color Consistency

Ensure the red Ochre Powder maintains a consistent color throughout the batch. Inconsistent color can lead to undesirable results in your final product or application.

Price Comparison

Request quotes from multiple suppliers to compare natural red iron oxide price. Remember that the cheapest option may not always be the best in quality—balance price with other essential factors.

The critical factors for buying Natural Red Iron Oxide

When considering the purchase of natural red iron oxide powder in Iran, also known as hematite or ferric oxide, there are several important factors to consider to ensure that you obtain a product that meets your specific requirements. Natural red Iron Oxide Pigments are widely used in various industries, including pigments, construction, ceramics, and the production of iron. Here are some key factors to consider before making a purchase:

Purity and Composition

The purity of Natural Red Iron Oxide is a critical factor. Different applications may require different levels of purity. Ensure that the product meets the purity specifications suitable for your intended use. The chemical composition of the iron oxide should also align with your specific application requirements.

Color Shade and Hue

Natural Red Iron Oxide comes in various shades of red, ranging from orange-red to deep burgundy. The desired color shade depends on the intended application, such as paint, plastics, or concrete. Manufacturers often provide color charts or specifications to help you choose the right hue for your needs.

Particle Size Distribution

The particle size of iron oxide particles can significantly impact the properties of the end product. Depending on the application, you may require a specific particle size distribution for optimal performance. For instance, pigments for paints or coatings may need fine particles for better dispersion, while construction materials may require coarser particles for improved durability.

Chemical Stability

Assess the chemical stability of the natural red iron oxide manufacture, especially if it is exposed to various environmental conditions. Stability is crucial to ensure that the product does not undergo unwanted chemical reactions or changes over time, affecting the end product's performance.

Batch Consistency and Quality Control

Consistency in quality from batch to batch is crucial, especially if you are using Natural Red Iron Oxide in a production process. Reliable suppliers adhere to stringent quality control measures to ensure consistent product quality. Request information about the supplier's quality control procedures and specifications for the product.

Packaging and Handling

Consider the packaging options available and choose iran red oxide Suppliers that suit your handling and storage requirements. Proper packaging helps prevent contamination and ensures the product's stability during transportation and storage. It's also important to check if the packaging complies with safety and regulatory standards.

Regulatory Compliance

Verify that the Natural Red Iron Oxide complies with relevant industry standards and regulations. This is particularly important for food, pharmaceuticals, and cosmetics applications. Ensure that the supplier provides documentation and certifications confirming compliance with regulatory requirements.

Supplier Reputation and Reliability:

Choose a reputable supplier with a history of providing high-quality products and reliable service. Look for reviews, testimonials, or customer references to gauge the supplier's reputation. A dedicated Red iron oxide factory will likely provide consistent quality and timely deliveries.

With over 30 years of experience in producing various industrial micronized powders and an experienced team with extensive knowledge of pigments, Farayand Powder Alvan Co. has been a reputable supplier in various industries and is honored to provide technical consultation to customers for the best and most economical solutions.

Applications

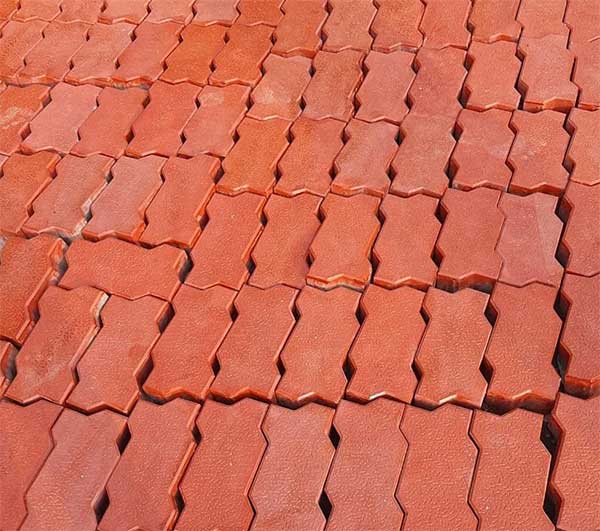

One of the biggest users of Iron Oxide Pigments is building materials industry. Uses include coloring the concrete products and mortar because of their acceptable dispensability and good strength.

Our iron oxides are suitable for coloring cement, concrete and concrete products, roofing tile asphalt and send lime bricks and offers considerable cost saving up to 50% in comparison with other synthetic products.

Paints industry can be considered as another biggest user of Iron Oxide Pigments. Most of the paint applications require applying micronized and good grades of pigments to acquire the best coloring effects.

Efficient test on paints, marine coating in which our iron oxides are used, shows a perfect performance than other similar products. Iron oxide is also ideal to be used in varnishes and stains.

Iron Oxide can be used in production of color master batches for the plastic industry since it’s considered as a heat stable material. Masterbatch is a concentrated mixture of pigments additives encapsulated during a heat processing to a carrier resin which is thereafter cooled and cut into granular shapes.

Masterbatch provides the processor to color raw polymer economically during the plastics manufacturing process.

Various shades of Iron Oxides are added to mortars, concrete blocks, surface areas and other building components to make the best of building exteriors and provide endless possibilities for designers and architectures.

Such colored finishes are also applied to restore heritage building by matching colors of the blocks and plasters with that of the existing structures.

Iron Oxides are widely used in preparation of leather colorants. Our iron oxide is free from heavy metals and hence preferred by the industry.

During the past years, iron oxide has been used for manufacturing of leather products it provides constant colorant on leather without having a negative effect on lifetime of leather like some other similar products.

Iron oxides match other applications such as:

|

|

|

|

|

|

|

|

|

|

|

|