General methods of test for pigments and extenders

Part 9: Determination of pH value of an aqueous suspension

1- Scope

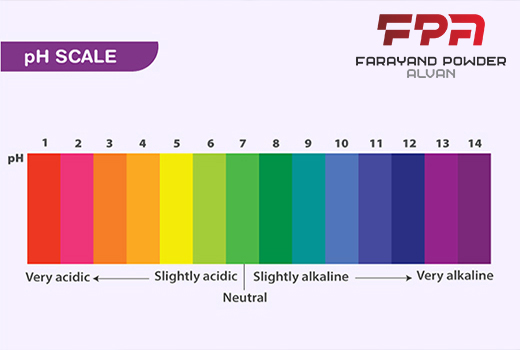

This document specifies a general method of test for determining the pH value of an aqueous suspension of a sample of pigment or extender.

2- Normative references

The following documents are referred to in the text in such a way that some or all of their content constitutes requirements of this document. For dated references, only the edition cited applies. For undated references, the latest edition of the referenced document (including any amendments) applies.

ISO 15528, Paints, varnishes and raw materials for paints and varnishes — Sampling

ISO 18451-1, Pigments, dyestuffs and extenders — Terminology — Part 1: General terms

3- Terms and definitions

For the purposes of this document, the terms and definitions given in ISO 18451-1 apply.

- ISO and IEC maintain terminological databases for use in standardization at the following addresses:

- ISO Online browsing platform: available at https://www.iso.org/obp — IEC Electropedia: available at http://www.electropedia.org/

4- Reagents

4.1 Distilled or demineralized water, in the pH range of 5,0 to 8,0.

Because water rapidly absorbs carbon dioxide, the water shall be protected from access to the atmosphere.

4.2- Buffer solution, 0,1 % KCl (p.a.), prepared using water specified in 4.1.

The preparation of a buffer solution is optional but recommended.

5- Apparatus

5.1- Glass container, made of chemically resistant glass, fitted with a ground glass or rubber stopper.

Glass container shall be cleaned before each use and to be rinsed with the corresponding water, see

above. The rubber stopper shall not have been used for any other purpose.

5.2- pH measuring device, capable of measurement to 0,1 unit, calibrated against buffer solutions of

known pH value at the temperature of the test.

© ISO 2019 – All rights reserved 1

iTeh STANDARD PREVIEW

(standards.iteh.ai)

ISO 787-9:2019

https://standards.iteh.ai/catalog/standards/sist/ecc45689-e07e-4776-8bb8-

105c5d0b00ad/iso-787-9-2019

ISO 787-9:2019(E)

5.3- Balance, with an appropriate accuracy.

6- Sampling

Take a representative sample of the product to be tested according to ISO 15528.

7- Procedure

Carry out the determination at room temperature.

Prepare a 5 % to 10 % (mass fraction) suspension of the product under test, using water (4.1) or the buffer solution (4.2), in the glass container (5.1). Stopper the container and shake, roll or stir it vigorously for sufficient time. Allow it to stand for 5 min, and determine, to the nearest 0,1 unit, the pH value of the suspension. Alternatively, the suspension may be filtered beforehand.

If the product does not disperse easily in water, a wetting agent should be used. In this case, up to 5 ml pure ethanol or methanol may be used but care should be taken to ensure that the minimum quantity is used. The neutrality of the wetting agent should be checked once by making a blank determination. If a wetting agent is used, the volume of water shall be reduced so that the original concentration of the suspension is maintained.

The type and quantity of wetting agent used shall be stated in the test report.

Record the pH value to the nearest 0,1 unit and record the temperature of the suspension to the nearest 1 °C.

8- Expression of results

Report the result to the nearest 0,1 unit.

9- Test report

The test report shall contain at least the following information:

a) the identification of the product tested;

b) a reference to this document, i.e. ISO 787-9;

c) if used, the type and quantity of wetting agent;

d) the result of the test as indicated in Clause 8, and the test temperature;

e) any deviation, by agreement or otherwise, from the procedure specified;

f) the date of the test.

........................................................................................................

With over 30 years of experience in producing various industrial micronized powders and an experienced team with extensive knowledge of pigments, Farayand Powder Co. has been a reputable supplier in various industries and is honored to provide technical consultation to customers for the best and most economical solutions.